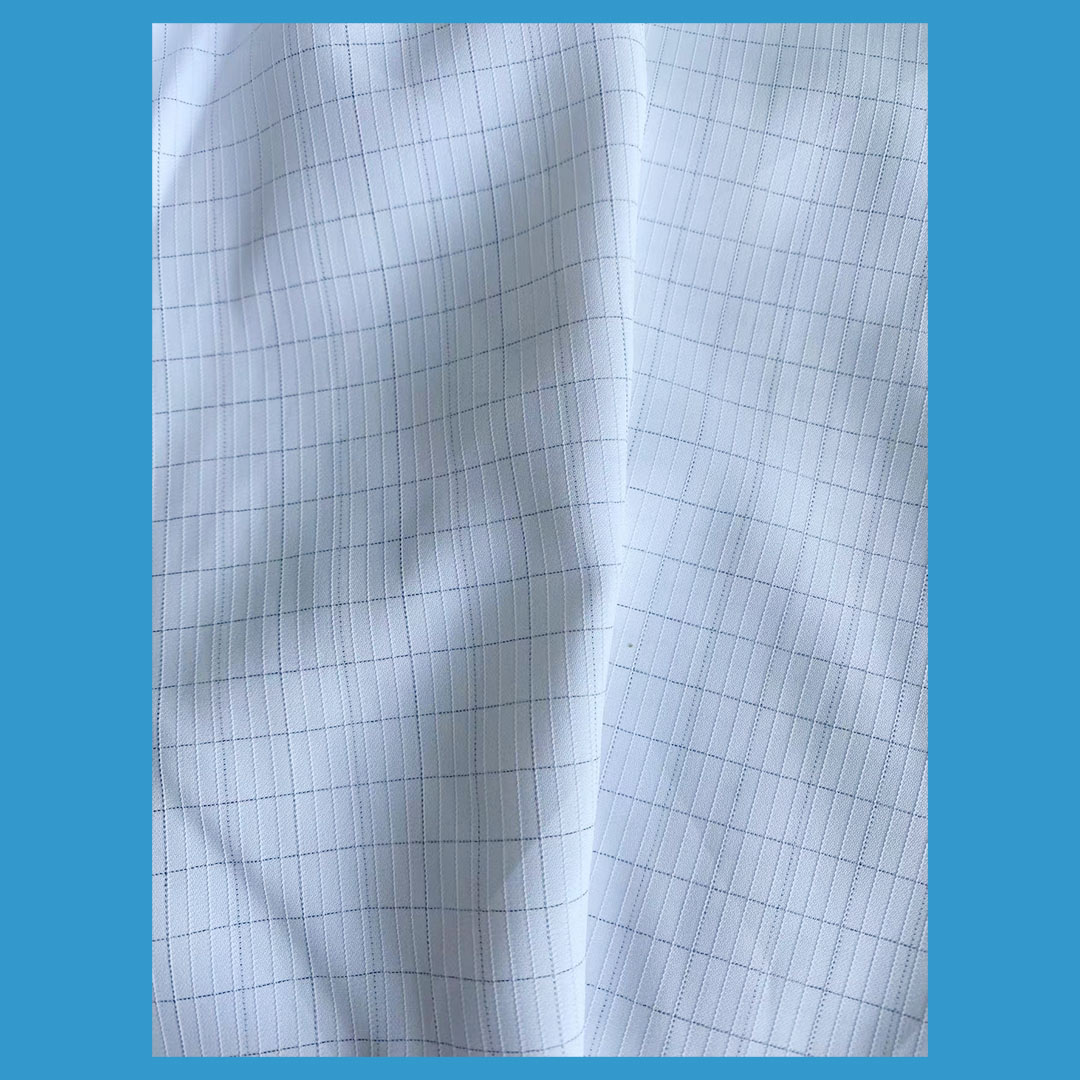

This section describes the ESD gingham

Antistatic gingham can be used in pharmaceutical factories, especially in clean rooms and dust-free environments in drug production sites. This kind of cloth can effectively prevent the accumulation of static electricity, thereby reducing the dust adsorption and particle pollution caused by static electricity, which is very important for the quality control of drugs. Maintaining a dust-free, sterile environment is key to ensuring the safety and quality of drugs during the production process of pharmaceutical plants, and electrostatic adsorption of dust may destroy this environment.

Specifically, the application of anti-static gingham in pharmaceutical factories has the following advantages:

Prevent particle pollution: Static electricity is easy to absorb dust, particles and other small substances, anti-static cloth can avoid these particles attached to the staff, to maintain the cleanliness of the drug production environment.

Ensure employee safety: Certain drugs or chemicals are very sensitive to static electricity, and anti-static cloths can reduce the risk of sparks or accidents caused by static electricity.

Compliance with clean room standards: Clean rooms in pharmaceutical plants usually have strict electrostatic control requirements, and the use of anti-static materials can help meet relevant standards.

Antistatic gingham can be used to make work clothes, especially in industries with strict electrostatic requirements, such as electronics, pharmaceuticals, chemicals, precision instrument manufacturing, etc. Work clothes made of anti-static checkers can provide static protection and ensure the comfort and safety of employees.

Here are some of the main advantages of using antistatic gingham to make work clothes:

Effective ESD prevention: The conductive fibers in the ESD check cloth can quickly export the accumulated static electricity of the human body, preventing static electricity from affecting sensitive devices, medicines, or the production environment.

Dustproof performance: Antistatic work clothes can reduce the adsorption of dust and particles caused by static electricity, so as to ensure the cleanliness of clean rooms or dust-free environments, especially suitable for pharmaceutical factories and other places with high requirements for health and environmental cleanliness.

Durability and comfort: Antistatic gingham is usually blended with polyester or cotton fibers and conductive fibers, which has good wear resistance, softness and breathability, ensuring a comfortable experience for the wearer at work.

Meet industry standards: Work clothes made of this fabric often meet industry-specific anti-static and clean standards, such as ESD (electrostatic discharge protection) standards required by electronics factories or GMP (pharmaceutical manufacturing quality management practice) requirements.

Therefore, the antistatic gingham is very suitable for the production of work clothes that require electrostatic control and a clean environment. If you need to produce work clothes, you can also customize them according to the specific requirements of different places, such as strengthening protection and improving air permeability.